BESPOKE FRAMING

Tailor-made frames to compliment

your artwork & your space.

HANDCRAFTED FINE ART FRAMING

From natural wood to anti reflective glass,

we use the finest materials to handcraft your frames

ONLINE ORDERS ARE CLOSED FOR 2024

Please note that any online orders placed after the festive cut-off date (8 December 2024) will be processed with care and attention once our factory re-opens on Thursday the 9th of January 2025

Frames are available to purchase instore, while stock last.

Consider these 5 Points when building your custom frame

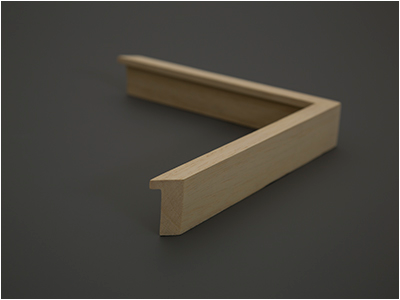

Natural

We custom-make a natural wood frame and sand it to ensure an even and smooth finish.

This method embraces all the “flaws” and “imperfections” in the wood and highlights them as being part of what makes the product unique rather than perfect.

Our natural wood range includes: Obeche, Beech, Kiaat, Ash, Maple, Oak and many more that can be sourced regionally.

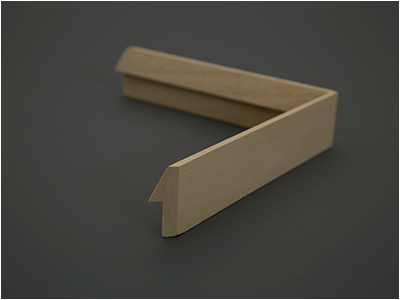

Stain

For stained frames, we use raw Obeche wood which is sanded and then stained to match one of the many colours that can be created from mixing the primary colours together.

Once the wood has been stained, it receives a final coat of sealer to protect the wood from the elements.

Show Grain

This product is named Show Grain as the actual grain of the wood shows through the paint.

This effect is achieved when raw Obeche wood is sanded, joined and then spray-painted with Duco spray paint. This method ensures an even finish throughout.

A wide range of colours can be achieved through the spectrum, simply bring us a sample and we will match it is as closely as possible.

Duco

Raw wood is treated with layers of primer and paint that fill the natural grain in the wood, achieving a silky smooth finish. A wide range of colours can be achieved through the spectrum, simply bring us a sample and we will match it as closely as possible.

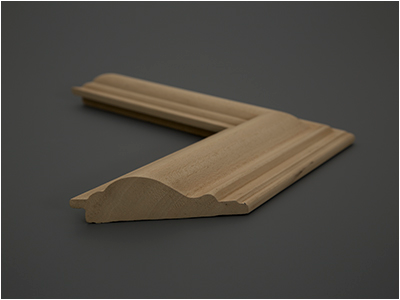

Synthetic

We stock, and can source, a wide range of synthetic mouldings. These mouldings are made out of synthetic wood and emulate the look of a wooden frame.

Leafed Frame

This extremely specialised process begins with the raw Obeche moulding. It is then spray-painted and the process of hand foiling the frame begins.

Thin layers of gold or silver foil are gently placed onto the moulding using shellac as an adhesive. A thin layer of treatment is then applied to the foil to change the colour into the desired end result.

This hand-made finish takes days to complete and as a result an extended turn-around can be expected when choosing this option.

Aluminium

We offer a wide range of smooth aluminium frames in various colours and sizes. Come in and chat to a consultant to find the right one for your artwork.

WINDOW MOUNT

A window is cut out of mount board in your chosen colour, and the artwork is hinged to the board

at the top. Traditionally, a second board is then used to protect the artwork from the back.

The window size and border size are chosen for aesthetic reasons and vary according to personal preference.

This method will crop the image slightly and therefore it is not ideal for works where the signatures

are on the edge or you do not wish to crop.

DOUBLE WINDOW MOUNT

The same technique is applied as with a single window mount, however an additional window

is cut leaving a visible inner border. This second window is usually an alternate colour

and has a width of around 5 – 10mm.

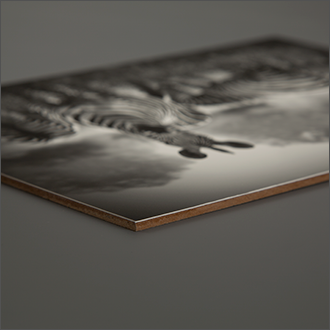

FLOAT

Once an artwork is adhered to a substrate, it can be “floated”. This means that the artwork is simply

adhered on top of a backing board, leaving a visible backing gap all around the artwork.

This gives the visual impression of the artwork floating slightly above the backing.

Substrates such as Triplex, can be reverse bevel cut to enhance the effect.

RAISE

A raise works hand-in-hand with a float finish - the combination is simply referred to as a “Float and Raise”.

A raise adds an additional board, of variable depth, behind the artwork to be floated.

Thus, raising it higher within the frame to give the float more visual depth.

FRAME TO IMAGE

No additional borders are left around the outside of the artwork and the image is fitted straight

to the edge of the frame. This is the most economical method of framing as there is no additional cost

for mount board or extra finishing.

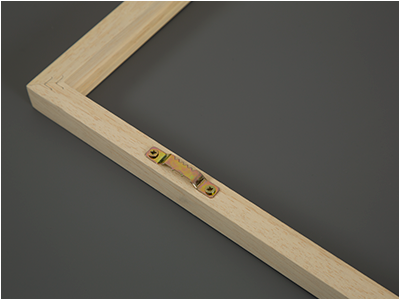

Strapping

Small pieces of double-sided archival tape are placed at even spaces around the edge of the artwork. The artwork is then strapped to a backing board by pulling the adhesive tape around the back of the board and then adhering it once tight.

This method can be archival or non-archival depending on the backing board used.

This method means that the artwork will never be completely flat as it allows for organic movement as it responds to temperature fluctuations.

Hinging

The artwork is adhered to the back of a window mount board using small segments of archival tape. A backing board is then adhered to the back, along one edge, allowing the window mount to swing open for easy removal of the artwork.

This method can be archival or non-archival depending on the backing/mount board used. This method means that the artwork will never be completely flat as it allows for organic movement as it responds to temperature fluctuations.

Clear Glass

Low Iron

Clear Glass

Plexiglas

Orms Blue

Anti-Reflective Museum

70% UV Protection

AR92

Anti-Reflective Museum

92% UV Protection